Circular co-creation hub

South West Flanders is known as the manufacturing region in Belgium. 1 out of 3 manufacturing companies in Belgium is located in this region. They are often family businesses from the textile, metal and plastics processing sectors that grew out of the traditional flax industry. For these SMEs, there is a compelling demand to transform into an industry that deals more sustainably with available materials and raw materials.

The Circular co-creation hub (CICO HUB) joins forces to bring companies together and support them in this transition to circular entrepreneurship.

Bringing all actors together

Collaboration with actors from different backgrounds and with different competences often brings surprising ideas to light. This platform therefore aims to increase knowledge on waste valorisation and circular entrepreneurship, discuss problems and barriers and create (chain) cooperation.

Where are we now? What can and are we already doing? What challenges do we still have to overcome?

We're a platform for manufacturing companies, custom companies, waste processing companies, service providers, companies active in the sharing economy, knowledge centres, creative enterprises,... with the central theme: waste valorisation and circular economy.

The circular future of (production) waste: valorisation of residual flows

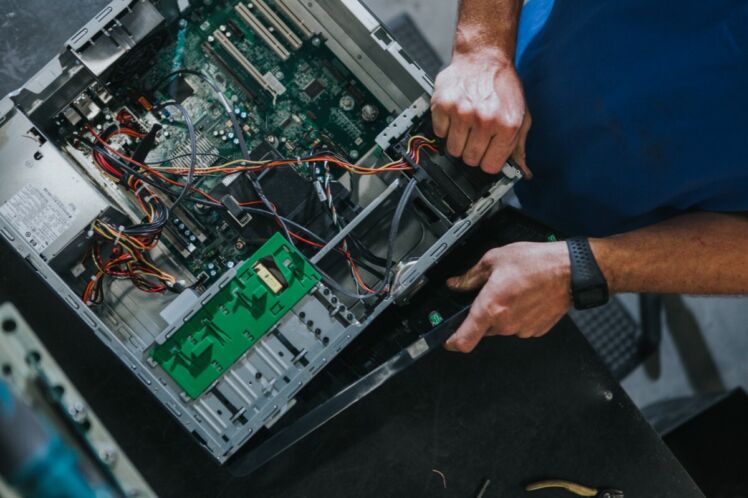

As of April 2021, within this part of the project, 3 manufacturing companies were selected to be given the opportunity to identify and explore their residual streams in collaboration with students and design companies in order to then co-create new products and a valorization of their residual streams with a customized company.

In 2023, a similar track was set up with the city of Kortrijk. Students and designers got to work with event flags and heras cloths to develop new products or services for the city and its citizens.

Design region Kortrijk in collaboration with Voka West Flanders, Howest, Intercommunale Leiedal, WAAK and W13 (social economy and tailoring companies) and with the support of ESF and Flanders Circular.

Project 2024: Focus on circular matchmaking

In 2024, the various partners Designregio, Leiedal, Voka West Flanders, Howest and Deltagroep are once again joining forces to further promote the circular economy in the region.

Through information sessions, trainings and show moments, we inform and sensitize companies, organizations and citizens about the circular economy.

With one-on-one conversations and the right matchmaking, we bring parties together to build circular value chains together to enable circular entrepreneurship.

Project 2023: A playful future for event flags

Every promotion, every event, every occasion involves a visual campaign. What could be better than making it shine on a flag or banner? But visual city marketing also leaves its mark. The flags and banners embody the temporary identity of the event. After the event, a trail of trash is left behind. Is this waste useless?

CICO Hub in 2023 focused on finding waste streams within the city to work with and design a circular destination for; the Heras cloths and event flags left behind after events in the city of Kortrijk.

A few designers were invited to transform this material and give it a new thoughtful life. Giel Dedeurwaerder, Saartje Allosserie, Pjotr Vandierendonck, Arend Vandenberghe and Yani Vandenbranden started a quest to transform waste into something useful, something beautiful, something that deserves a second life in our city.

Project 2022: The circular future of (production) waste: valorization of residual streams

As of April 2021, within of the project the circular future of (production) waste, 3 production companies were selected to have the opportunity to identify and explore their residual streams in collaboration with students and design companies to then come up with new products and a valorization of their residual streams in cocreation with a custom company.

The companies are Fluvius, Sunconfex and Moerman, they were paired with 8 designers: Studio Allossa, Huho Design, EDMIRE.design, Tillup Design Studio, Studio AMA, Studio L'Atitude, Surplace and Studio Obi-One.

Sébastien Hylebos

Sébastien assists businesses in innovation and design. He is also responsible for projects on circular economy and digitalisation in cooperation with companies and designers.