CICO Hub 2022

As of April 2021, within of the project the circular future of (manufacturing) waste, 3 manufacturing companies were selected to be given the opportunity to work with students and design companies to identify and explore their residual streams and then cocreate with a custom company to come up with new products and a valorization of their residual streams.

The companies are Fluvius, Sunconfex and Moerman, they were paired with 8 designers: Studio Allossa, Huho Design, EDMIRE.design, Tillup Design Studio, Studio AMA, Studio L'Atitude, Surplace and Studio Obi-One.

Moerman

Moerman, based in Meulebeke, is a manufacturer of floor and window squeegees. Rubber sheets are optimally divided into parts for the different products. During the production process, however, rubber residue is inevitable. Studio L'Atitude, Surplace and Studio Obi-One were given the task of finding solutions for these ruber residues.

- Studio Obi-One

With few operations, the longer synthetic and EPDM rubbers can be reused as tree ties. The material has ideal properties to be used outdoors. The thick, soft and flexible properties of the rubber also prevent constrictions in the trunk.

- Studio L’Atitude

Meet BASHED; the up-cycling story where two residual streams met to form a duo of functional and aesthetic products. Using residual rubber as padding and used truck tarpaulin 'bache' as a shell, Studio L'Atitude brought to life the BASHED_Punchbag and BASHED_Pouf.

- Surplace

Together with Moerman and other local players, Surplace developed a sustainable tile for flat roofs. The tile, consisting entirely of waste streams, requires no permanent fixings, thus extending the life of both the floor and the underlying roof structure.

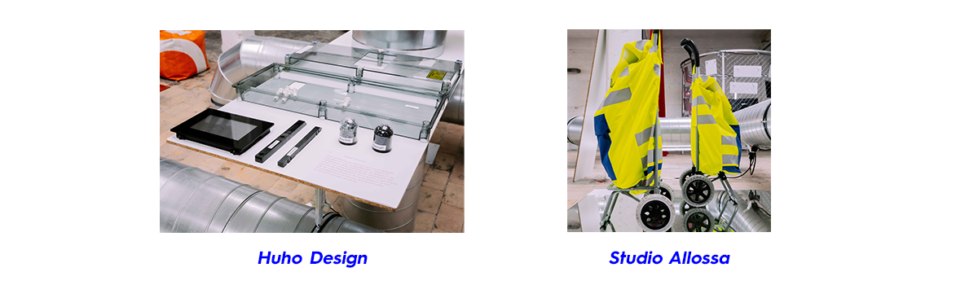

Fluvius

Grid operator Fluvius participated with 3 different residual streams. Given the digital transformation, there is a waste of analog electric meter covers. In addition, there are old light fixtures that are being replaced by smaller low-energy lights. Third, the merger of Eandis and Infrax created a stream of unusable work clothes. Edmire, Studio Allossa and Huho Design each addressed one of these challenges.

- Huho Design

With a mountain of 900 tons of meter lids, some possibilities arise. However, given the more complex composition of the lids, this is not easy, so the best option appeared to be to convert the meter lids into granules. That way, after a recycling process, the meter lids can be incorporated into new, meaningful products.

- Studio Allossa

The merger of Fluvius and Infrax in 2019 created a flood of unusable work clothes. The parka jackets are an example of this. Unfortunately, given their protective function, these cannot be recycled to date. Studio Allossa chose to upcycle the coats into a rainproof shopping trolley; "Flor, the Fluvius Trolley." In addition to their annual support of The Food Bank, Fluvius can now offer the trolley to the collector to transport the food package.

Sunconfex

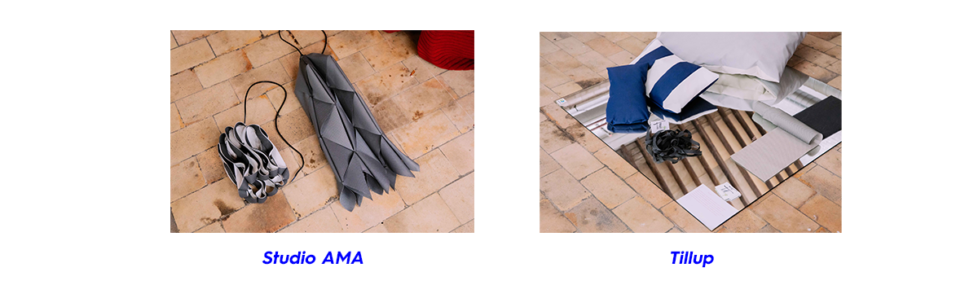

Sunconfexis a well-known player in made-up solar shading fabrics. All awning fabrics are custom-made for each exterior project. In the process, long cut pieces are created. The smaller pieces of these cannot be reused in the process. These scraps were submitted to Studio AMA and Tillup.

- Studio AMA

The designs of the various outdoor products find their origin in the materiality of the sun protection textile and its capabilities: this both aesthetically and functionally. The designs highlight transparency, ductility, resilience and layers.

- Tillup

Based on its strong quality for exterior use, Tillup used the cuttings to develop new outdoor applications. From this was born their "Suncollexie"; different products for outdoor use, such as a windbreak and cushions in different sizes.