Wondering Stories: Ghent University

How 3D printers can make your business more sustainable too – Wondering Stories: Ghent University

Remember those first 3D printers, about twenty years ago? You could print the craziest gadgets with them. The possibilities just seemed endless. Today, 3D printing has outgrown its infancy and is becoming more and more a lever for sustainability. Companies can now attend a workshop at Ghent University’s design.nexus research group to see how 3D printing can help their business too.

Ghent University is playing a pioneering role in this, and that’s all thanks to a match made in heaven between two industrial designers who found each other in Kortrijk. Yannick Christiaens is an expert in product styling and design. Francesca Ostuzzi, an Italian with a heart for sustainability, came to Belgium eight years ago. Both were convinced of the potential of 3D printing at the time, but were growing somewhat frustrated.

Francesca: “In Milan, we had an open lab where anyone could come and use a 3D printer. In this way, the general public could get acquainted with the technology whereas we as researchers got insights into various techniques. At least, that was the idea. But in reality, 3D printing was only being used for gadgets. Understandable, since it was all very new and exciting. But still, I felt disappointed, especially as I could see the technology’s potential in terms of sustainability.”

Yannick: “I want to make meaningful things, not just toys for the sheer joy of printing.”

Numerous applications

There are plenty of meaningful things and stories to be found at the Kortrijk campus of Ghent University, where Francesca and Yannick and their research group got themselves settled. They demonstrate the ever-growing applications of 3D printing and how this technology has penetrated our lives, often without us realising it. Applications range from orthotics to artificial hips, from horse riding helmets to coffee machine parts, and from drum kit parts to ship propeller parts. At their research lab, you can also see one of their latest realisations: a curved plastic platform with 3D printed connectors on which you can lie down. As it turns out, it has a very specific function.

Yannick: “This is the test version of a device used in breast cancer treatment. Women have to lie on it in a kind of crawling position, which allows for better and more direct radiation without damage to normal tissue. Master and PhD students from our department developed this device, on the recommendation of the medical community. We made about 20 of them, which are now being tested in several hospitals.”

This clearly shows why 3D printing has already had a major breakthrough in the medical world: you can develop customised solutions at a–comparatively–much lower cost. Think prostheses, dental crowns, even many hearing aids are now made with a 3D printer.

It seems logical that industry will be next, recognising and using the benefits of 3D print technology.

Francesca: “In traditional industry, you first have to develop a model, which costs a lot, and then you have to produce enough to recoup the model production costs, meaning you end up with endless identical copies that have to serve everyone. With 3D printing, the cost per copy is higher, but you don't have to spend resources on developing a model.”

“The car industry is also rapidly moving towards 3D printing,” says Yannick: “We worked on a project with Honda, the big Japanese player in the car industry. When Honda exports cars to Europe, there are always non-compliant parts with the European market. Yet, those parts have to stay put during shipping, otherwise the car wouldn't work and the electronics would get messed up. With 3D printing, we can prepare those parts here, just in time.”

This project really puts industrial design engineering to the test: the look and feel requirements in the automotive industry are very high, much higher than for, say, a new washing machine part.

Printing @ home

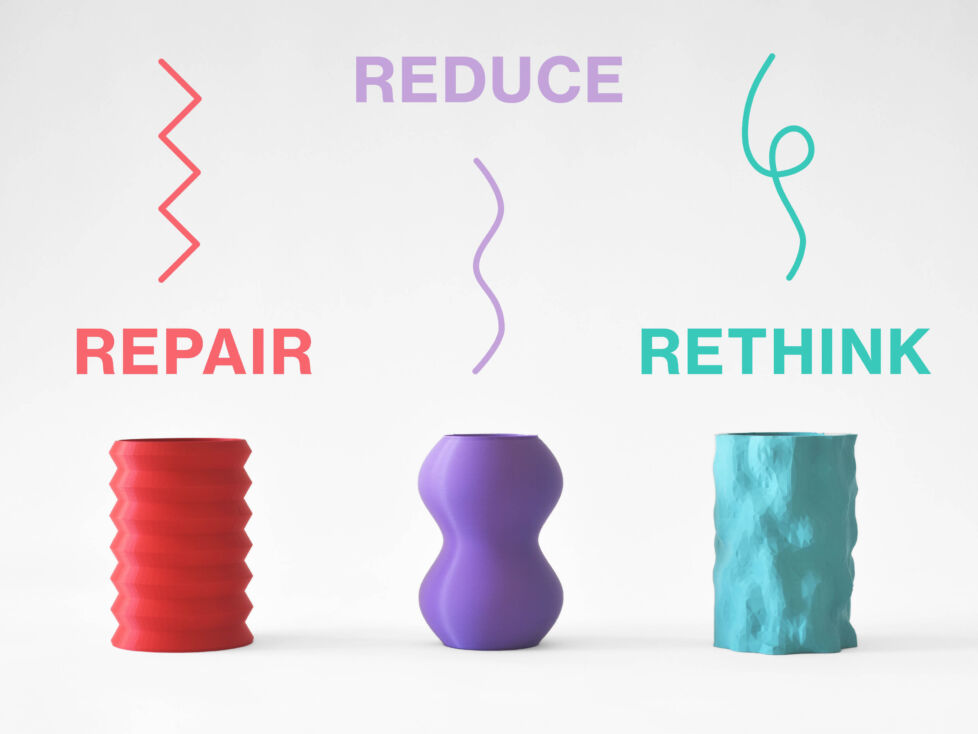

In recent years, a growing number of studies have shown the potential positive impact of 3D printing on sustainability, in all 3 R’s: Repair (e.g. printing defective parts on site), Reduce (working more efficiently and therefore in a more sustainable, less expensive way) and Rethink (using the possibilities of 3D printing to reinvent the whole product and surrounding system).

Francesca uses household electrical appliances as an example: “'With the current energy crisis, people tend to think: I'll just go and buy a new coffee machine or a fridge when a part breaks down, because the new models use less energy. But what you need to realise is that producing new appliances, transporting them to retailers and sometimes even having them delivered to your doorstep requires much more energy than repairing your old appliance. And thanks to 3D printing, this can be done quickly and sustainably. You just let the retailer know what part you need, so they can 3D-print it for you. On demand, without the need for stockpiling or for having that one part transferred from a larger warehouse, let alone send the whole device.”

“Or you can just print it yourself, at home,” Yannick adds. “3D home printers have gotten a lot better in recent years, and cheaper too. Meanwhile, the codes you need can be found on specialised platforms. In time, you might be able to download that code from the manufacturer's website, for a small fee. So there are no disadvantages: the consumer is helped quickly and doesn’t have to buy a new appliance, even if it has been out of stock for a long time. And the manufacturer doesn’t have to stockpile spare parts.”

Workshops for businesses

Ten years ago, The Economist headlined that 3D printing would bring about a new industrial revolution. But it turned out to be soon at the time to jump to that conclusion, Yannick realises: “The excitement of the early days created unrealistic expectations. We would be able to 3D print everything, the sky was the limit. In the meantime, the first printers still had teething problems and the printing materials were of poor quality. Printing complex items was simply impossible at the time. Thus, companies' first introduction to 3D printing turned out into a big disappointment. It seemed like a hype, and some people still think the hype will pass. But in recent years the quality has improved enormously. Machines have gotten a lot better and are quite affordable now, even for small budgets.”

Since last year, Ghent University designers have been checking in with companies, if only to sow a seed.

Yannick: “Companies that want to work on sustainable entrepreneurship and want to know how 3D printing can help them do so, can book a workshop with us. Some companies are still totally unaware of the possibilities of 3D printing–what with the fast changing technology–while other companies are already using it but don’t know which steps to take next. Our goal is not to design or program for them, but to help them explore the possibilities and develop a roadmap.”

Text and image: Revista

The 3 trumps of 3D printing

WONDERING STORIES

With the WONDERING STORIES series, Designregio Kortrijk brings unique stories of companies, organisations or designers to life in its network, thanks to the unique input of copywriters and visual creatives. Designregio Kortrijk matches and guides.