Shaping Matter Event

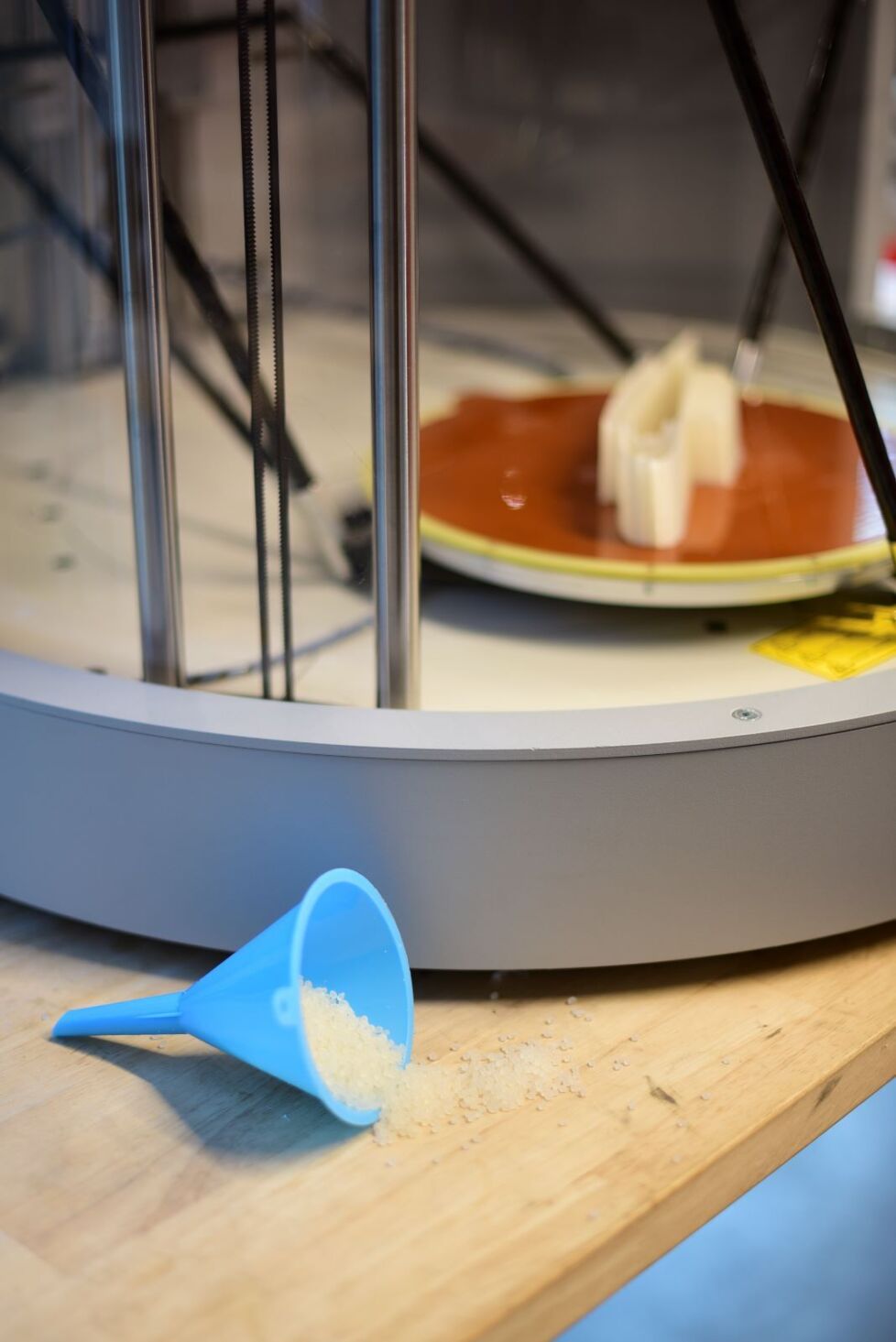

Pellet Additive Manufacturing (Pellet AM) or Fused Granulate Fabrication is emerging as a key technology in 3D printing using raw thermoplastic pellets. Learn about its variations, applications, advantages, and challenges.

Join Howest/Industrial Product Design (IPO) and partners to explore why Pellet AM could be a game-changer—and whether it is right for you.

Practical

Date: 02/04/2025

Location & organization:

Howest Campus Kortrijk Weide - The Penta

Parking:Follow directions to parking P3 & P4

Entrance fee: €159 (excluding VAT) per person, for both visitors and exhibitors (invoiced after the event). Howest students can attend at no cost.

Cancellation policy: Cancellations can be made at least one week before the event.

Language: English spoken

Target audience:

- Companies involved in plastics/ceramics/metal injection molding prototyping, design, and manufacturing

- Academic researchers in Additive Manufacturing (AM)

- Service providers in Additive Manufacturing (AM)

Program overview

(in detail to be confirmed)

08.45 Welcome with coffee

09.30 Introduction

Becky Verthé (Howest - Belgium)

A welcome word from host Industrial Product Design educational program at Howest

09.40 Pellet AM state of the art, Howest research

Katrijn Sabbe (Howest - Belgium)

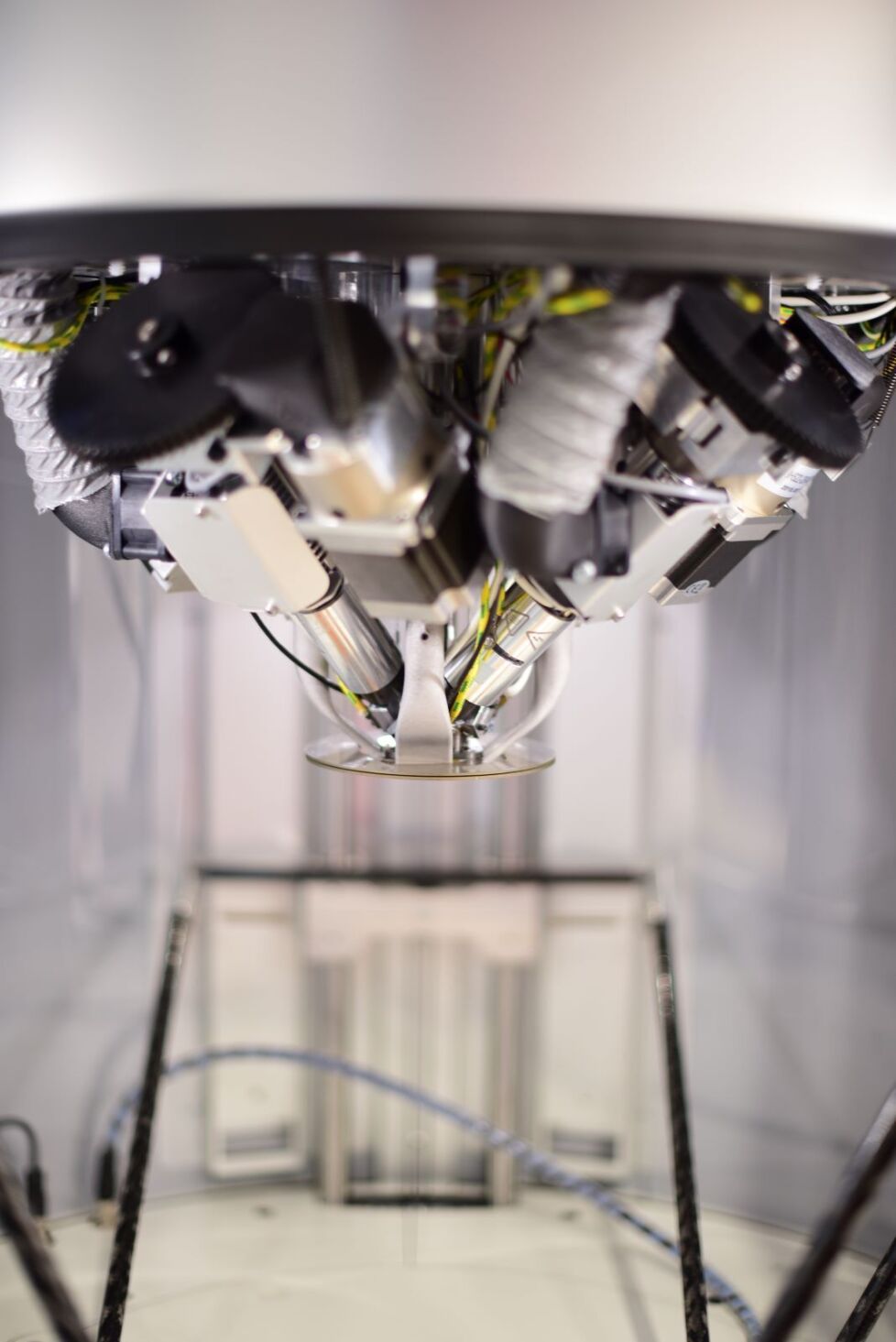

An overview of current Pellet AM technologies and machines according to output sizes, applications, materials,... What are the possibilities, applications and challenges? What have we learned from an ongoing research focusing on industrial cases with a Pollen AM 3D printer?

10.15 To be confirmed

10.40 Break & networking exhibitors

11.10 To be confirmed

11.35 Injection molding and Pellet AM technology, use of certified engineering polymers, metallic alloys and ceramics

Charles-Edouard Dendoncker (Feronyl - Belgium)

Feronyl is specialized into developing and manufacturing advanced mechanical systems out of multi-materials. Through Pellet AM technology, we fasten the development cycle between prototyping and challenging serial ramp-ups in injection molding. Different use cases by Pellet AM technology.

12.00 Guided tour of Industrial Design Center infrastructure

12.45 Walking lunch & networking exhibitors

13.30 To be confirmed

13.55 Implementation of recycled polymers in pellet printing: a material and hardware challenge

Pieter-Jan Bulcke (Bulcke Technical Printing - Belgium)

14.20 Break & networking exhibitors

14.50 Pellet AM technology optimized by specialised software

Verena Witt (AIM3D - Germany)

AIM3D has been in the field of 3D printing with granulate materials for over 8 years. Showing the current technology, what opportunities have been met in industrial applications. Furthermore, through the development of the Voxelfill software, typical limitations of layer built objects for prototyping or final parts, can be overcome. We will show an depth view on how Voxelfill works, what challenges have been met and how it can help optimize your projects, also in the known filament 3D printing applications.

15.15 Large-scale application of robotic arm 3D printing: key design principles

Pieter Maelegheer (Footprint Inc - Belgium)

Robotic arm 3D printing is widely used for large-scale applications such as tooling, interior design, and construction. To fully leverage this technology, it’s essential to consider some key design guidelines.

15.40 Pellet printing capabilities at Centexbel

Xander Praet (Centexbel - Belgium)

An overview of Centexbel's current pellet printing infrastructure. Going over some results from previous projects and providing an outlook for upcoming projects involving additive manufacturing. Furthermore, we will look at the challenges we faced in the past and how the market is evolving to address these.

16.05 To be confirmed

16.30 Reception & networking exhibitors